PRODUCTS

Steel Wire Rope

Home

PRODUCTS

Steel Wire Rope

Home

PRODUCTS

Steel Wire Rope

Important Warnings

Read all warnings before using this publication. Failure to follow warnings and instructions can result in serious injury of death.

Kobizon Enterprise Co. assumes no responsibility for the use or misapplication of any product sold by this firm.

Responsibility for design and use decisions rests with user.

Wire rope is a machine. Understand and respect it.

Like any machine, it needs proper care and maintenance for optimal safety and long service life.

Rated Capacity

Rated capacity is the load which a new wire rope may handle under given operating conditions and at an assumed design factors.

There are, however, other terms used in the industry which are interchangeable with the term Rated Capacity.

There are: WLL, SWL, Working Load Limit, Safe Working Load, Rated Load Value, Resulting Safe Working Load.

All catalog ratings are based upon usual environmental conditions, and consideration must be given to unusual condition such as extremely high or low temperatures, chemical solutions or vapor, prolonged immersion in salt water, etc.

Such conditions or high-risk applications may necessitate reducing the Working Load Limit.

A design factor of 5 is chosen most frequently for wire rope.

(Operating loads not to exceed 20% of catalog Breaking Strength.)

Operating loads may have to be reduced when life, limb or valuable property are at risk or otherwise, new rope should be used.

A design factor of 10 is usually chosen when wire rope is used to carry personnel.

(Operating loads not to exceed 10% of catalog Breaking Strength.)

Attachments must have at least the same Working Load Limit as the wire rope used

Clips, sockets, thimbles, sleeves, hooks, links, shackles, sheaves, blocks, etc. must match in size, material and strength to provide adequate safety.

Keep out from under a raised load

Do not operate load over people. Do not ride on load. Conduct all lifting operations in such a manner that if equipment were to fail or break, casualties would be caused. This means KEEP OUT FROM UNDER A RAISED LOAD.

DO NOT OPERATE LOADS OVER PEOPLE AND KEEP OUT OF THE LINE OF FORCE OF ANY LOAD.

Avoid shock loads

Avoid impact, jerking or swinging of load. Working Load Limit will not apply in these circumstances because a shock load is generally significantly greater than the static load.

Inspect wire rope regularly

Check the general condition of the wire rope. Also, look for localized damage and wear, especially at wire rope attachments. Poor performance of wire rope can often be traced back to worn or wrong-sized sheaves, drums, rollers, etc. Look for kinks, broken wires, abrasions, lack of lubrication, rust damage, crushing, reduction of diameter, expansion or other obvious damage. If any of these conditions exists or if there is any other apparent damage to the wire rope, retire the wire rope.

Destroy, rather than discard, wire rope to be retired

Wire rope that is not destroyed might be used again by someone not aware of the hazard associated with that use.

Destroying wire rope by cutting it up into short pieces is the best way.

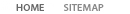

Production Flow Chart

Superiority of Manho Rope & Wire Ltd.'s Steel Wire Rope

· As all wire ropes are manufactured by updated facilities, the quality of wire rope is Consistent and excellent.

· High quality grease is used to protect against corrosion and to improve the life of the wire rope.

· Manho wire rope can be produced in accordance with these international specifications.

KS D 3514 Wire Rope

JIS G 3525 Wire Rope

FS-RR-W-410E Steel Wire Rope

ISO-2408 Steel Wire Rope

API-9A Wire Rope

· Kobizon has been approved as a wire rope producer by international inspection institutes such as

| KS D 3514 | Wire Rope (1966. 4) |

| JIS G 3525 | Wire Rope (1989. 5) |

| DNV(Det Norske Veritas) | Steel Wire Rope (1983. 2) |

| GL(Germanischer Lloyd) | Steel Wire Rope (1978. 4) |

| LLOYDS(Lloyd's Register of Shipping) | Steel Wire Rope (1976. 10) |

| NK(Nippon Kaiji Kyokai) | Steel Wire Rope (1975. 1) |

| ABS(American Bureau of Shipping) | Steel Wire Rope (1969. 12) |

| KR(Korean Register of Shipping) | Steel Wire Rope (1976. 1) |

| RINA(Registro Italiano Navale) | Steel Wire Rope (2009. 4) |

| API(American Petroleum Institute) | Wire Rope (2006. 10) |

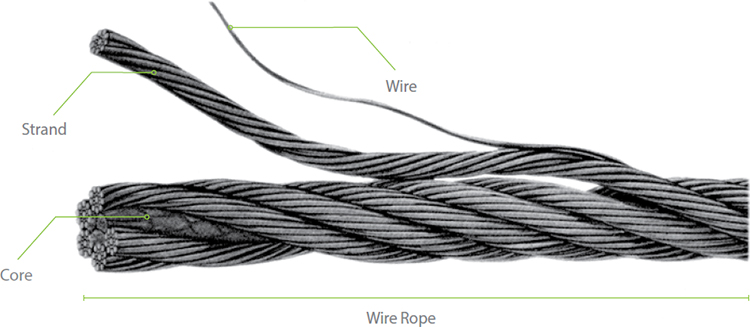

Components of Wire Rope

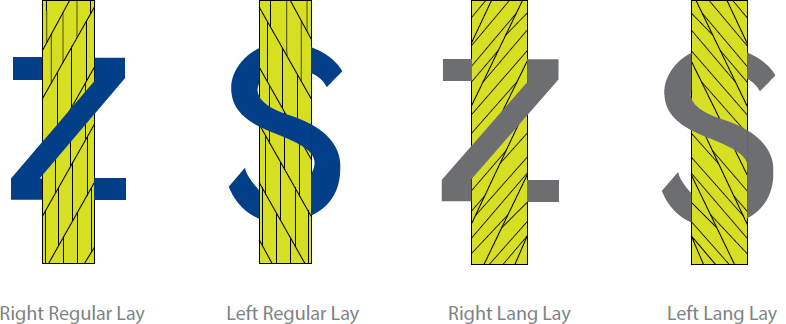

· Lay of Wire Rope

There are two main types of lays: REGULAR and LANG. Regular lay ropes is more flexible than Lang lay ropes, so they are more suitable for eye splicing. Lang lay ropes have longer life than Regular lay ropes as they are worn out evenly in being used.

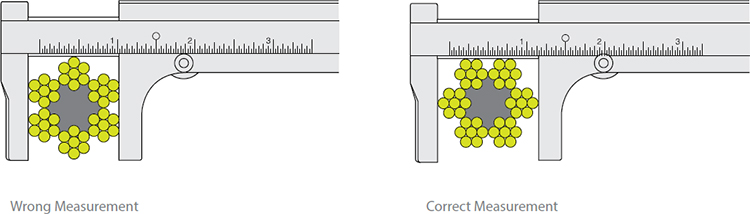

· How to Measure Rope Size

The size of wire rope is the diameter of the circle which will just enclose all of the stands.

The correct method is to measure over any pair of opposite strands. (See drawings)

How to Handle Steel Wire Rope

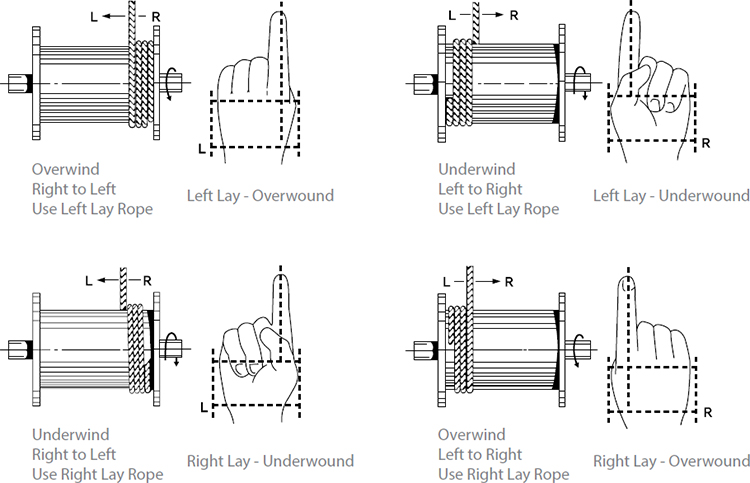

• Winding Method of Drum or Winch

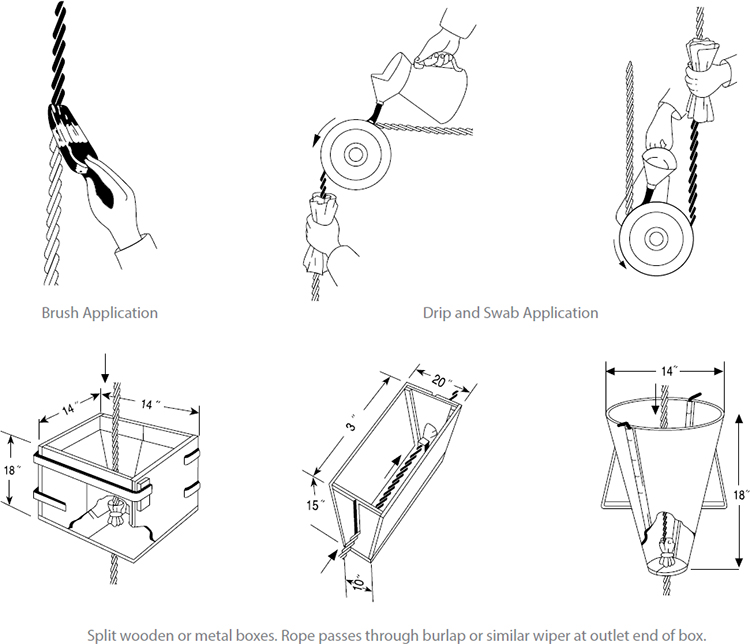

• Lubricating Methods

Below are illustrated some simple methods of lubricating ropes externally while in use. There are of course other lubricators and cleaning devices available commercially, and still others which can readily be fabricated in a plant or local work-shop.